Plumbing Materials

Plumbing is an important part of your home. Over the years many different materials and techniques have been used to supply and distribute water for homes. Some of these materials present problems and may need correcting. Please use this page as a resource to educate yourself on the pros/cons and tradeoffs of the various materials and techniques.

Polybutylene

Polybutylene (PB) was a plastic manufactured between 1978 and mid-1995 for use as piping in home plumbing systems. It was inexpensive and offered plenty of advantages over other materials, such as flexibility, ease of installation, resistance to freezing. Pipes made from polybutylene were installed in up to 10 million homes in

the United States during that period. Despite its strengths, production ceased in mid-1996 after scores of allegations surfaced claiming that polybutylene pipes were rupturing and causing property damage. In the homes that still contain this material, homeowners must either pay to have the pipes replaced or risk a potentially expensive plumbing failure.

How Does Polybutylene Fail?

Two studies in particular in papers published by the University of Illinois at Chicago have shown that certain disinfectants can react with the polybutylene and cause it to flake apart at any location within the PB piping system. Small fractures can deepen over time and eventually work their way to the pipe’s exterior, allowing water to escape. Some manufacturers, however, claim that the majority of leaks occur at joints and unions, which is where a leak would likely appear if a pipe were improperly installed. Despite this contention, class-action lawsuits filed against PB manufacturers have been successful and resulted in payouts to homeowners reaching $1 billion.

Polybutylene Pipes Should Be Replaced

Although no regulations require the replacement of polybutylene piping with other material, many plumbers recommend doing this, at a cost several thousand dollars. Leaking can happen without warning and can result in flooding and serious damage to a home’s interior if it is not immediately stopped. PB pipes installed behind sheetrock can leak unnoticed for long periods of time and cause mold and water damage. It is far cheaper to replace polybutylene pipes before they fail and release their contents onto floors, appliances and furniture. They can also reduce a home’s value or prolong its time on the market.

Homeowners might face higher insurance premiums or be denied coverage entirely. For homeowners who are concerned about this problem and wish to replace the PB piping in their home with copper or other material, there are companies that specialize in this type of work.

Identifying Polybutylene

Use the following tips to identify polybutylene plumbing. Polybutylene pipes are:

- usually stamped with the code “PB2110”;

- flexible and sometimes curved, unlike rigid piping materials such as copper;

- not used for waste, drain or vent piping;

- most commonly grey in color, but they can also be white, silver, black or blue. Blue PB is used primarily outdoors and should only be used to carry cold water. Be aware that black or white pipes might not be polybutylene (they might be polyethylene or PVC, respectively).

- ½” to 1” in diameter.

Galvanized

What are galvanized pipes?

Galvanized pipes are steel pipes that have been dipped in a protective zinc coating to prevent corrosion and rust. Galvanized piping was commonly installed in homes built before 1960. When it was invented, galvanized pipe was an alternative to lead pipe for water supply lines. Today, however, we have learned that decades of exposure to water will cause galvanized pipes to corrode and rust on the inside.

How long do galvanized pipes last?

No piping system lasts forever, but galvanized pipes have a lifespan of between 40 to 100 years. If your home’s pipes are from the 1960s or earlier, they are likely nearing the end of their functional lifespan.

However, there’s a reason galvanized pipes are no longer used in modern construction: the risk they pose to a home’s water supply and people’s health.

Are there safety risks or concerns with galvanized piping?

By far, the most significant problem related to galvanized pipes is the mineral deposits that accumulate within the piping. Over time, it causes a reduction in water pressure and pollutes your home’s water. And as rust and corrosion deepen, they comprise the piping system’s stability and cause leaks.

As old and corroded galvanized pipes age, they can release accumulated lead into your tap water. That lead can pose significant health concerns, as ingesting too much can result in lead poisoning, and its symptoms include fatigue, headaches, insomnia, nausea, constipation, abdominal pain, and reduced cognitive abilities. High doses of lead are of particular concern with children, as it can hinder their brain development and lead to lifelong health issues.

What do galvanized pipes look like?

When first installed, galvanized pipes look like nickel in color. But as they age, galvanized pipes may appear much duller, lighter, or darker, depending on their environment. We’ve also seen homes where the water pipes have been painted, so it can be difficult to tell at first glance.

Do galvanized pipes contain lead?

The galvanized pipes installed on water lines between 1880 and 1960 were dipped in molten, naturally occurring zinc. Naturally occurring zinc is impure, so these pipes were bathed in zinc that also contained lead and other impurities. The zinc coating elongated the life of the steel pipes but added small amounts of lead and other substances that could harm inhabitants.

Additionally, if your galvanized pipes were ever connected to lead plumbing (including service lines) there is more cause for concern. The corrosion inside galvanized steel pipes could have trapped small pieces of lead. Even if the lead piping was removed years ago, the galvanized steel pipes could still periodically release the trapped lead into the water flow.

The only way to ensure that lead is not mobilized from plumbing to tap in a given home is to fully replace the galvanized plumbing and any lead service lines.

What other problems can galvanized pipes cause?

- Low Water Pressure: Due to the restriction of the line, corrosion in galvanized pipes can cause lower water pressure throughout your home.

- Uneven Distribution of Water: If some of your taps have low water pressure but others don’t, this could be a symptom of galvanized pipes. Corrosion can build up unevenly. Also, part of the galvanized pipeline could have been replaced in your home but not everywhere.

- Discoloration of Water: Galvanized pipes can release iron and cause discoloration. A clear indicator of this is a brown stain on a porcelain sink.

- Leaks: Given enough time, galvanized pipes will rust through and cause more damage to your home.

What does the galvanized piping removal process entail?

For a permanent fix, replacing all galvanized pipes is the best option, as it ensures all the rust and lead in the piping system is completely removed. While repiping an entire house is a big project, the payoffs are well worth the investment. The repiping process begins with an inspection to identify any unique problems that should be addressed. A replacement piping material is then selected, typically copper, PVC, or PEX for freshwater lines and ABS or PVC for waste and drain pipes.

After protecting your home from possible damage, qualified plumbers use specialized tools to locate existing pipes, remove them, and replace them with new ones.

Depending on your home’s size, a repiping project can take up to a week to complete. As pertaining to cost, the pipe material you choose and how much piping you need determines the final price. Older and vintage homes often have special considerations, such as plaster walls, that can result in the job taking longer and costing more.

Cast Iron

The gold standard of plumbing lines, cast iron pipes have been around for decades and are found most often in older homes, apartments and condos. Most commonly used in DWV (drain, waste, vent) systems, cast iron pipes were first utilized in sewer drainage systems due to the material’s durability, its ability to handle water and its resistance to damage. However, many cast iron systems are in homes and apartments built into most homes pre-1975 and are less likely to be found in newly built residential homes. This is due to the fact that as these lines and systems have aged over the decades, it’s been found

that the cast iron material deteriorates over extended periods of time, and many homes built with cast iron DWV systems in place have started to see plumbing problem related to the pipes life expectancy, which is anywhere between 50 and 100 years. And so the question is, do you replace them? If so, with what? And—what are some of the disadvantages of having a cast iron pipeline in your home?

The Alternatives (Plastic, Relining)

If you already have a home with leaking or quickly deteriorating cast iron pipes, it’s definitely time to start thinking about either replacing your DWV system with a different material or relining it. If you’re considering gutting your old pipeline—or even sections of your system—and replacing it with today’s new gold standard, you’ll likely be left making the choice between PVC (polyvinyl chloride) or ABS (acrylonitrile butadiene styrene), which are two plastic polymer-based alternatives. Lightweight, affordable and less prone to corrosion, these plastic polymer systems are much easier to repair and are considered the best options to choose from for homeowners in the current era.

Relining is also an option for homeowners looking for a solid fix while keeping their existing pipes. This involves trained specialists inserting an epoxy-based lining into the deteriorating cast iron pipes, which essentially creates a new interior lining—making the pipe as good as new. Of course, you’ll have to do this operation while the pipe still has some exterior and interior integrity, or the lining won’t be able to match the form.

Common Faults and Problems with Cast Iron Pipes

For the most part, corrosion is your primary concern with cast iron pipes. It can happen in a variety of ways, however one of the primary causes of accelerated deterioration is homeowners and DIY fixers trying to use substances and acids like Drano to clear clogs in their lines. Not only is Drano—and similar brands of pipe cleaners—corrosive to metal piping, but it’s also harmful to humans and incredibly bad for the environment. More often than naught, a snaking tool or plunger is more than enough to clear up any

line-related clogging

Another fault of cast iron pipes is simply long-term reliability. The longer you have cast iron pipes in your home, the higher the chance of some sort of plumbing failure. This problem only builds upon itself as cast iron pipes are very heavy and difficult to fix, leading to expensive and messy repairs. And any sewer backups created by your cast iron DWV system can lead to a variety of home issues, from water damage to pest infestations and even mold growth. Common defects with cast iron include cracks lengthwise, defective pipes and the bottom of the pipe thinning out, which inevitably causes weeping.

What Should You Do if Your Home Has Cast Iron Pipes?

First, it’s best to determine if your home really has cast iron piping in it. A qualified plumber can do a deep inspection of your abode’s plumbing system and will let you know if your entire DWV is made of cast iron or just sections. From there, they will also be able to inform you on the health and level of deterioration showing in your pipes—if they are cast iron. If everything’s looking good, you don’t need to fret about it too much—healthy cast iron is quite durable and strong, hence why it was used in the first place—however make a note of it and schedule annual or bi-annual check-ups on pipes. It’s also probably best to have some money set aside to make inevitable repairs or replacements to your current system.

If there are signs of deterioration already present in your cast iron pipes, getting those relined or replaced as soon as possible will inevitably save you big bucks in the future. (Cast iron waste pipes can last anywhere between 50 and 100 years. However, it may be time to replace cast iron pipes long before their lifetime is up.) As previously mentioned, cast iron pipes are heavy and difficult to repair, and can cause various issues for homeowners in the long run.

Copper

History Of Copper Pipe

The Ancient Egyptians were the first documented civilisation to make widespread use of copper piping within the Pyramids – albeit a very crude implementation – believing that the dead were meant to have the same luxury as those of the living. The Egyptians also demonstrated similar methods to the Indus Valley Civilisation, in removing wastewater and bringing clean water in, as cities became highly centralised and urbanised. The Pyramids are an impressive example of copper’s longevity – so much so that a 4,500-year-old tomb of King Sahure gave clear evidence of an elaborate copper pipe system installed within it, used as a drainage system.

In the UK, copper was first used as an alternative to lead systems, although it gained popularity in the 1960s as the demand to replace lead piping and ageing systems increased. Lead pipes were phased out and made illegal due to increasing concerns over lead poisoning, as the longer water is in contact with lead, the greater the risk of acquiring it. Today, properties built after 1970 no longer use lead systems, and it is advised that if there is a system that is still operating, it should be replaced immediately.

It was during World War Two that plastic piping became more commonly used and the application of copper declined due to its importance in the war effort. At this time, plastic pipes were generally used for protection of cables for radar systems, but slowly became prevalent as a potable water pipe system material during the 1970s.

Plastic pipe systems are dangerous to the environment as they cannot be easily recycled, and the push back against plastics is gaining traction as governments and corporations look to distance themselves from unnecessary plastic usage within their products. In the water sector, organisations and public buildings are shifting to using copper due to its natural protection against chemicals in the water supply, meaning copper pipes don’t need the same treatments that plastic pipes need.

Copper Pipe Advantages

- Copper Plumbing Pipes Are Durable: Copper plumbing pipes have proven to be incredibly durable. This piping material is able to handle pressure of up to 1000 psi. The average lifespan of copper piping will range from 50 – 70 years depending on variables such as the surrounding climate, water quality, and operating patterns. This material is able to withstand the demands of large to small families for a lifetime. Another reason copper plumbing pipes are popular is because of their ability to withstand cold and hot temperatures. These pipes are less likely to freeze throughout the winter season when compared to other materials. In addition, copper piping is resistant to corrosion from water and includes a sufficient reactivity rate.

- Copper Piping Does Not Contaminate Water: While other types of metal pipes such as lead, iron, and galvanized steel have faded out, copper plumbing pipes have stood the test of time because they don’t release dangerous materials into water. In addition, copper pipes are recyclable and are able to be installed outside.

- Copper Pipes Are Lightweight: Copper plumbing pipes are easy for professionals to install since they’re not heavy. In addition, this material is highly flexible and is able to extend over large distances throughout the home. Since copper is extremely durable, it does not require support materials or equipment to withstand your requirements.

- Copper Piping is Less Harmful For the Environment: Unlike PEX and PVC pipes, the manufacturing process for copper plumbing pipes is environmentally friendly since it releases less dangerous emissions and chemicals into the environment. In addition, copper pipes are able to be recycled at the end of their lifespan.

- Copper Plumbing Pipes Are Fire Resistant: Since copper piping features a high thermal rating, it is resistant to fires. For homeowners concerned with using fire retardant materials, copper makes an excellent choice.

Copper Pipe Disadvantages

- Copper Pipes Are Expensive: The major reason for the rise of alternative piping is cost. Copper plumbing piping is more expensive than plastic piping, such as polyvinyl chloride (PVC) or cross-linked polyethylene (PEX). The latter is quickly becoming a standard in many residential applications for its strength and flexibility.

- Copper Piping May Add a Metallic Flavor to Water: While it is minimal, copper plumbing pipes may add a metallic flavor to your drinking water, which may be off-putting for some homeowners.

- Copper Pipes Cannot Withstand Acidic Water: If you rely on well water or water with high acidity levels, you may have issues with the copper pipes in your home a couple of years after the installation. We only recommend using copper plumbing pipes in areas that are connected to a sanitary municipal water supply system.

- Copper Plumbing Pipe Maintenance Tips: Proper maintenance is essential for ensuring the longevity and functionality of copper piping. Visual inspection is crucial in identifying potential issues. Regularly checking areas such as basements or exposed sections of the plumbing system allows homeowners to spot any visible signs of water dripping, which could indicate a leak. Repairs can be made promptly and less expensively by catching these problems early, preventing further damage.

Green deposits on copper pipes, known as verdigris, signify improper soldering. This residue occurs when flux, used during the soldering process, is not properly wiped off. The flux residue acts as an acid that slowly eats away at the pipe, leading to corrosion and leaks. Visual inspection can help identify areas with excessive verdigris, similar to the green patina on the Statue of Liberty. Wiping off this residue with a rag using an acidic solution such as vinegar, lemon juice, or salt can minimize the potential for future leaks and corrosion. Alternatively, warm water and dish soap can also work.

When joining copper pipes or fittings, it is important to ensure cleanliness. This includes using a sand cloth or fitting brushes to clean the surfaces before soldering. Any dirt or debris left inside the joint can cause issues during the soldering process and compromise the integrity of the connection. Thoroughly cleaning the surfaces before joining will help ensure a secure and leak-free connection.

Regular visual inspections and proactive maintenance are key to maintaining copper pipes. Checking for signs of leaks, addressing them promptly, removing any verdigris residue, and ensuring clean joints when joining pipes can help prevent future problems and extend the plumbing system’s lifespan.

PVC

History of PVC Pipe

PVC has been around for over 150 years but only became widespread in the last 70 years. According to research, the discovery of PVC plastic happened on two separate occasions.

In 1838, French physicist Henri Victor Regnault first synthesized PVC plastic. Almost 40 years later, in 1872, German chemist Eugen Baumann was able to materialize PVC plastic again. Both scientists were not successful in replicating PVC plastic production. The first patent for PVC plastic wasn’t filed until 1913 by German inventor Friedrich Heinrich August Klatte.

By the mid-1900s, PVC plastic was used worldwide for furniture, flooring, medical tubing, electrical insulation, and more. In the 1980s, scientists made further improvements to PVC plastic as it was beginning to be used more for plumbing in new homes.

PVC Pipe Advantages

When you think of pipes for plumbing, chances are PVC pipes are the first thing that comes to mind. The white pipe is made of a synthetic plastic called polyvinyl chloride or PVC. Plumbing companies in Los Angeles are fully aware of the many advantages associated with PVC pipes, such as the following.

1. Resistant to Corrosion: Most older homes use galvanized steel, clay, or cast iron pipes for plumbing. These materials are highly prone to corrosion. Corroded pipes can easily crack or break, leading to major leaks in your home’s plumbing and drain system. None of these issues are associated with PVC pipes.

2. Easy to Install: Plumbers everywhere enjoy working with PVC pipes thanks to their ease of installation. Unlike steel pipes, PVC pipes are easier to cut to install. PVC pipe installation takes less time than steel pipes, giving you less time without working plumbing pipes.

3. Smooth Surface: If you ever touch a PVC pipe, you will notice its smoothness. PVC plastic pipe’s smooth surface provides less friction, producing efficient water flow for your home. Less friction in PVC pipes is also why they are used indoors because it allows for silent water flow.

4. Lightweight: Steel pipes are heavy and require more workforce and machinery to carry. PVC plastic pipes are lightweight, which makes them easier to transport and move from one job site to another. Heavier equipment requires more labor, and more labor usually equals higher costs.

5. Durable and Strong: PVC pipes are versatile because they can be used for indoor and underground plumbing. According to our technicians, indoor PVC pipes can last around 55 to 80 years, and underground PVC pipes can last 100 years before being replaced.

6. Resistant to Low Impact: Underground pipes must be sturdy for water transportation support. PVC plastic pipes for plumbing can handle water pressure without weakening. If it weren’t impact resistant, these pipes would have had a high chance of cracking or breaking. Thanks to PVC’s density, these pipes can withstand high impact. These plastic pipes are resilient enough to withstand small impacts without sustaining any damage.

7. Affordable: Homeowners and professional plumbing companies select PVC pipes because of their low cost. PVC pipes are an inexpensive material. Pipe replacement jobs for sewage line repair should cost significantly less PVC than steel pipes, given you don’t run into any major issues along the way. Pipe material is just one of the many things involved with pipe replacement cost, which you can read more about here.

8. Easy to Mold: Manufacturers can mold PVC plastic into any shape to fit every home. Because of its easy molding capabilities, PVC plastic is used to make pipes and pipe connections like valves, bends, elbows, and clips.

9. Eco-Friendly: Everyone does their part to be more earth-conscious. PVC plastic production produces fewer carbon emissions than galvanized steel and iron pipes. With PVC plastic, you will feel more eco-friendly thanks to fewer carbon emissions being released into the atmosphere.

When it comes to piping materials, PVC plastic has numerous advantages. PVC pipes are available in different diameter sizes and levels of thickness. This design helps plumbers have the suitable pipe that best fits your home.

Most PVC pipes are differentiated from another with various colors. PVC pipes are white but can have the following color marking on them.

- White: drains, waste, ventilation, and cold water supply

- Blue: cold water

- Dark Gray: cold water

- Green: sewer service

PVC pipes are never black to help differentiate them from ABS plastic, another alternative pipe material.

PVC Pipe Disadvantages

PVC plastic was designed to be a superior pipe for homes but has a few minor flaws. Here’s a further look into each PVC pipe issue.

- Weak to High Heat: While it may not stand up to heat as well as steel, PVC pipes can still withstand temperatures up to 140 degrees Fahrenheit. PVC pipes are vulnerable to fire since it causes the plastic to warp or melt.

- Could Freeze: PVC pipes may freeze during freezing temperatures. A frozen PVC pipe doesn’t always break, but any wet material inside can freeze and cause a buildup of pressure. To better deal with freezing weather, some PVC pipes come with insulation. Frozen pipes are more likely to burst whether they’re made of copper or plastic.

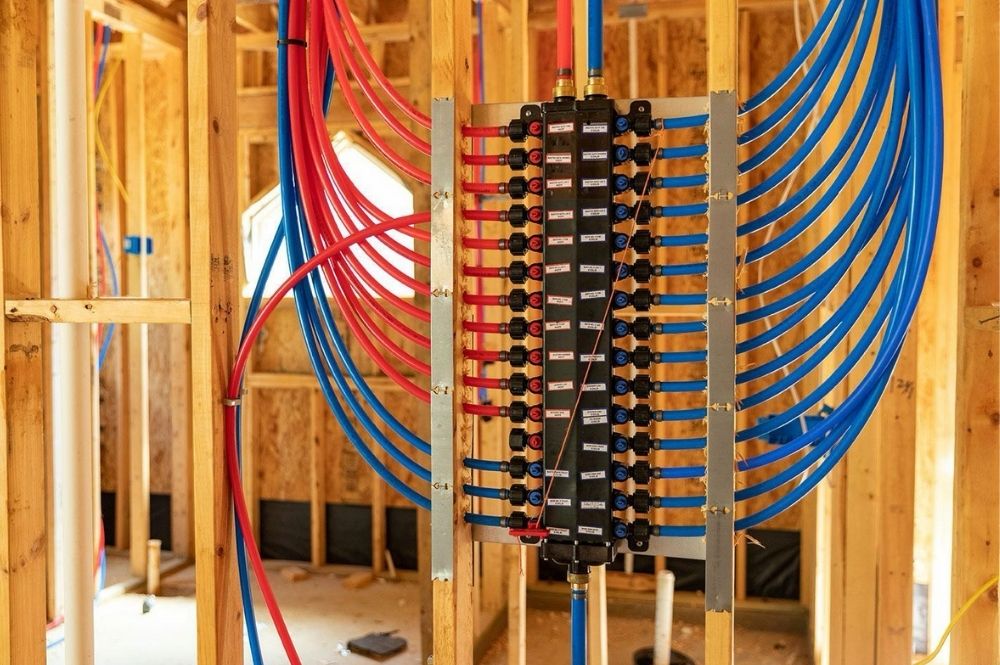

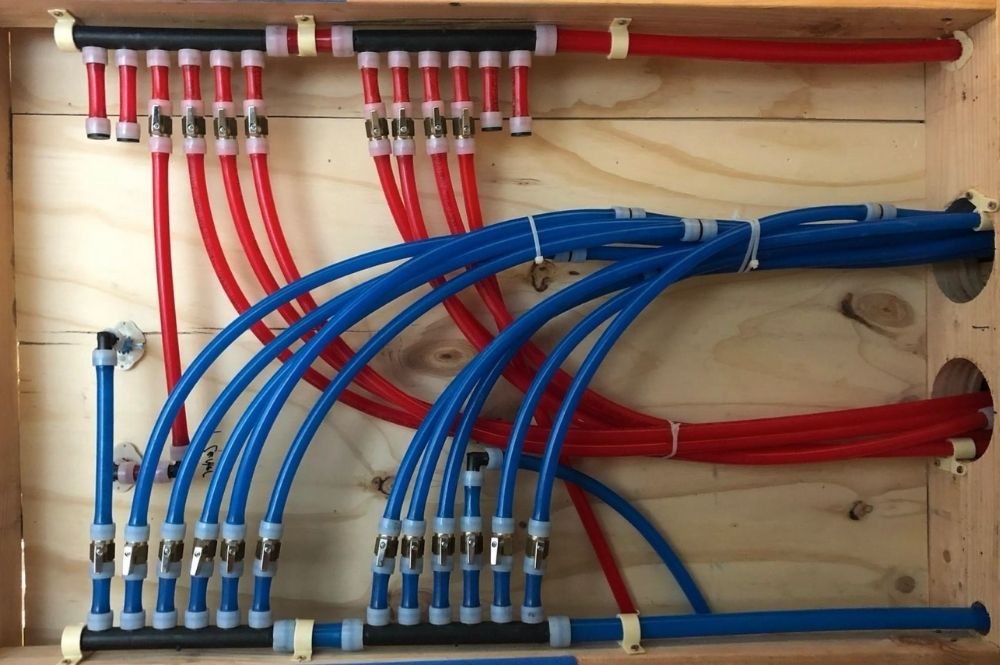

PEX

Cross-linked Polyethylene (PEX) pipes are the go-to pipes trusted by plumbers everywhere to safely deliver hot and cold water throughout your home. There are many reasons why PEX pipes are superior and a few reasons why they’re not the best option for your home. As a homeowner, you’ll gain insider knowledge on the advantages and disadvantages of PEX pipes. This information could be the deciding factor for your home’s pipe repairs, which can save you hundreds or thousands of dollars!

History of PEX Pipe

Unlike copper, which dates back to ancient times, PEX plastic was created in 1968 by German scientist Thomas Engle. The material was used in Europe for water supply plumbing but wasn’t used as frequently in the United States until 30 years ago.

PEX piping is a lot more common today and is available in three different types:

PEX-A: This pipe provides the most flexibility and is suitable for all water supply plumbing needs. It is also the most resistant to freeze cracking. PEX-A pipes are manufactured using peroxide.

PEX-B: PEX-B pipes are great for pools since it has increased chlorine resistance. These pipes also have great coil memory, returning to their original shape when they expand.

PEX-C: PEX-C plastic pipes are the lowest in price compared to the other two, but they may crack in freezing temperatures. It’s also the least flexible, so it is not commonly used.

Most homeowners don’t have to worry about choosing which type of PEX plastic pipe to install. Experienced plumbers will always select the best materials to do the job efficiently.

PEX Pipe Advantages

Did you know that over 60 percent of newly constructed homes have PEX pipes installed for water supply systems? This is because of a variety of factors that give PEX piping its overall stellar reputation.

Plumbing companies, contractors, and homeowners have sought PEX piping for the following reasons.

1. PEX Piping is Cost-Effective: This plastic pipe is easier to install and is one of the lightest options when compared to copper pipes. Its low installation cost means you will pay less for PEX and have high-quality piping in your home. Plastic pipes are also cheaper than copper pipes to produce, so those savings are passed down to the homeowner.

2. Ease of Installation: Thanks to its physical and usage flexibility, plumbers can use one single-length pipe to connect water lines in hard-to-reach places. PEX connections are easier to install since the fittings require less specialized tools to connect. PEX pipes are easy to install because their unique color-coding system is not available on other pipes. Blue pipes are for cold water, red for hot, and white/gray colored pipes are for both.

3. PEX Pipes Reduce Noise: You may hear water flowing through pipes because of loose pipes or high water pressure, but that’s not the case with PEX plastic. These pipes provide silent water flow, so you don’t hear running water while trying to enjoy music or watch a movie in your living room.

4. PEX Plastic is Durable: PEX pipes will not corrode over time like metal pipes. These pipes have a lifespan of 30 years with proper water treatment along with a yearly check-up from a professional plumber. PEX piping is also resistant to freeze-cracking, so it can handle temperatures of -40 degrees Fahrenheit without breaking, thanks to its ability to expand and contract.

5. PEX Pipes Are Energy Efficient: PEX plastic is an excellent thermal insulator for hot water. With PEX piping, water heater systems use less energy. This ensures that hot water from your home’s water heater arrives at your faucets without losing a lot of heat. With thick PEX piping, hot water will lose only one or two degrees of heat which isn’t enough to call it cold water. Homes provide shelter and protection from outside elements. It’s only fair that you use the best available materials for your home so it can continue to serve you and your family. With PEX piping, your family can depend on a good water supply system throughout your house.

PEX Pipe Disadvantages

PEX piping sounds like a fantastic option for water supply plumbing in every home, but it does have some drawbacks. Although it has many advantages, you should consider the following PEX pipes’ disadvantages in deciding whether this material is a good fit for your home.

- PEX Plastic Is Weak to Fire: The chances of a fire inside your home are very low, but it remains a nightmare scenario for any homeowner because you can lose everything in your home. But if there were a fire, PEX plastic pipes would melt, requiring new replacement pipes.

- Ultra Violet UV Light Sensitivity: PEX pipes don’t do well for outside plumbing even if it’s underground because UV light can penetrate through the dirt and affect PEX pipes. If left outside, PEX pipes will deteriorate and become useless. These plastic pipes should not be stored exposed to the sun.

- PEX Pipes Are Not Recyclable: If you are trying to implement an eco-conscious lifestyle, you will not want PEX pipes in your home. PEX plastic can’t be broken down like other plastics, like PVC plastic, for reuse. Discarded PEX can end up in landfills instead of being processed for reuse. This plastic can last 30 years so it isn’t like it’s disposed of every couple of years.

- Susceptible to Rodents: If your home has a rodent problem, it can affect your PEX pipes. On rare occasions, rodents have been shown to chew through PEX plastic. PEX pipes are very thick but they are still susceptible to rodent damage that can cause pipes to crack or break.

- Possible Leaching: Although uncommon, some homeowners and plumbing companies have reported a few PEX pipes leaching harmful contaminants like BPA (Bisphenol A) into the water supply. BPA chemicals can cause neurological, reproductive, and immunity issues.